Tainan Railway

Railways move goods and people safely from place to place including across continents at far higher speeds than any national or international road network will ever allow. This enhanced speed is achieved through building in safety factors that remove almost every barrier that otherwise would exist.

The first railway focus in the early 19th Century was on building bridges and tunnels and it was only found out later that some could have benefited from solutions that monitored possible damage by motorists (known some countries as bridge bashing) or flooding during severe storms. Railways have moved into the 21st century with both bridges and tunnels being progressively electrified around the world and as a result overhead wires can sway in high winds and the impact of ever increasing train speeds and heavy loads potentially has new implications for both track foundations and bridge constructions.

As a general rule of thumb, the higher the railway line speed the more likely that monitoring interventions in some form will be needed for such high profile projects.

The railway industry is one where the terminology used can at times require some clarification, even translation. Induced vibration means vibration caused by trains passing next to infrastructures, buildings, residential areas at great speeds where the movement of this rolling stock causes vibrations.

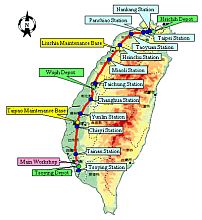

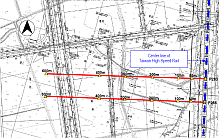

The Taiwan HSR line runs approximately 345 km from Taipei to Kaohsiung (Tsoying), passing 14 major cities and counties and 77 townships and regions. The line is a high capacity and high speed railway. It is capable of carrying over 300’000 passengers in a single day of operation. After commissioning, it is expected to reach a normal speed of up to 300 km/h, and ultimately 350 km/h, shortening the north-south journey time to within 90 minutes.

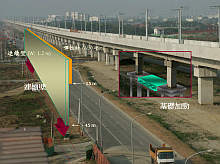

The Tainan Science Park, located in the Tainan County in southern Taiwan, will be a new location for many vibration sensitive high-tech factories. Realizing that the high-speed rail alignment passes through the Tainan Science Park, the Taiwan High-Speed Rail Corporation (THSRC) has set up design requirements such that during operation, the vertical vibration within 200 meters on either side of the rail centerline do not exceed 46 dB (10-6 inch/sec) in the high frequency range ( 12.5 Hz ) and do not exceed 68 dB in the low frequency range ( < 12.5 Hz ). Besides these measures to be taken, to satisfy the highly sensitive high-tech factories in the park, TSIP initiated the Vibration Mitigation Project, and the Vibration Measurement for Verification of Vibration Mitigation Effectiveness Project linked to that.

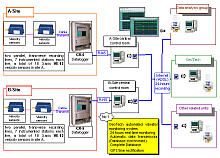

GeoTech Engineering Consultant Co., Ltd., a company who focuses on automated, remote and integrated geotechnical instrumentation monitoring systems as well as the development of corresponding database management software, is assigned by TSIP to accomplish the mitigation project.

The first railway focus in the early 19th Century was on building bridges and tunnels and it was only found out later that some could have benefited from solutions that monitored possible damage by motorists (known some countries as bridge bashing) or flooding during severe storms. Railways have moved into the 21st century with both bridges and tunnels being progressively electrified around the world and as a result overhead wires can sway in high winds and the impact of ever increasing train speeds and heavy loads potentially has new implications for both track foundations and bridge constructions.

As a general rule of thumb, the higher the railway line speed the more likely that monitoring interventions in some form will be needed for such high profile projects.

The railway industry is one where the terminology used can at times require some clarification, even translation. Induced vibration means vibration caused by trains passing next to infrastructures, buildings, residential areas at great speeds where the movement of this rolling stock causes vibrations.

The Taiwan HSR line runs approximately 345 km from Taipei to Kaohsiung (Tsoying), passing 14 major cities and counties and 77 townships and regions. The line is a high capacity and high speed railway. It is capable of carrying over 300’000 passengers in a single day of operation. After commissioning, it is expected to reach a normal speed of up to 300 km/h, and ultimately 350 km/h, shortening the north-south journey time to within 90 minutes.

The Tainan Science Park, located in the Tainan County in southern Taiwan, will be a new location for many vibration sensitive high-tech factories. Realizing that the high-speed rail alignment passes through the Tainan Science Park, the Taiwan High-Speed Rail Corporation (THSRC) has set up design requirements such that during operation, the vertical vibration within 200 meters on either side of the rail centerline do not exceed 46 dB (10-6 inch/sec) in the high frequency range ( 12.5 Hz ) and do not exceed 68 dB in the low frequency range ( < 12.5 Hz ). Besides these measures to be taken, to satisfy the highly sensitive high-tech factories in the park, TSIP initiated the Vibration Mitigation Project, and the Vibration Measurement for Verification of Vibration Mitigation Effectiveness Project linked to that.

GeoTech Engineering Consultant Co., Ltd., a company who focuses on automated, remote and integrated geotechnical instrumentation monitoring systems as well as the development of corresponding database management software, is assigned by TSIP to accomplish the mitigation project.

The purpose of this project is to obtain instrument-recorded in-situ ground vibration data for verification of effectiveness of vibration-mitigation measures implemented in Tainan Science-Based Industrial Park (TSIP) for reducing ground vibrations induced by the Taiwan High Speed Rail (THSR) train operations. The THSR track passes through the eastern edge of TSIP.

The vibration mitigation measures constructed in TSIP for reducing high-speed-running-train-induced ground vibrations consist of the following two specific measures:Stiffening the elevated guideway structure foundations in TSIP with foundation-stiffening blocks (FSB) that structurally link the pilecaps of the pile-foundations together in the longitudinal direction of the THSR alignment.

Constructing underground wave-barrier-wall (Diaphragm Wall) at approximately 30 m away to the west of and parallel to the THSR alignment.The elevated guideway structure segment in TSIP implemented with the vibration mitigation measures is approximately 4.85 km long from the THSR Chainage TK290+700.000 to TK295+548.716.

Instrument Recording Stations

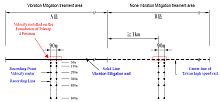

Since the THSR trains are not yet operational before vibration mitigation measures are constructed, no measurements of train-induced free-field ground vibrations can be made before implementation of vibration mitigation measures to provide reference ground vibration data to be used for comparison with the corresponding data obtained after mitigation. Therefore, two sites are required for ground vibration measurement.

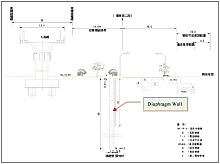

One site, referred to herein as “Site A”, is located in the mitigated structure section in TSIP; the other site, referred to herein as “Site B”, is located in the unmitigated structure section outside TSIP but close to Site A.

Site A: Located in Mitigated Section

Site A is located approximately at the middle of a selected approximately 10 consecutive 30-m-long girder-spans section of the mitigated elevated structures in TSIP.

A total of 14 instrumented recording stations, all from VE-13 Triaxial Velocity Sensors, are deployed for Site A. These recording stations are arranged in two parallel-lines perpendicular to and on the west side of the THSR alignment. The two recording lines are selected at approximately the mid-section within the 4.85-km long mitigated section of elevated structures in TSIP. Each recording line is aligned with the transverse centerline of each selected pier, which is pier 287 & pier 289. The two parallel, transverse recording lines are spaced with a distance in the longitudinal direction of the THSR alignment of approximately 90 meters or three 30-m-long-spans apart.

On each transverse recording line, seven (7) VE-13 instrumented recording stations are deployed. One station is located on the pilecap of the selected pile-foundation and the other six are located on the free-field ground surface at distances 70, 100, 200, 300, 400, and 600 meters away from the THSR alignment centerline.

There are 3 VE-13 measuring sensors at the station on the pilecap; two out of the three measuring sensors measure y-axis, y-axis & z-axis respectively, where y-axis is the direction of the train path, which is believed to be producing the most vibration.

Site B: Located in Unmitigated Section

Site B is located outside, to the south of the 4.85-km long mitigated structure section in TSIP in subsurface ground condition that is similar to that of the selected recording Site A.

In a one-to-one correspondence to the instrumented recording stations in Site A, a total of 14 VE-13 recording stations are also deployed for this recording site in the same pattern as that for Site A. The selected recording Site B is approximately 4.53-km distance away from the south end of the 4.85-km-long mitigated structure section.

The locations of the 14 VE-13 instrumented recording stations for each of Site A and Site B is shown schematically in Figure 4 and Figure 5. In this figure, the solid line represents the mitigated structure section in TSIP having vibration mitigation measures implemented; the dashed line represents a selected unmitigated structure section outside TSIP without any vibration mitigation measures implemented.

|

solution |

Product |

|

2 x 21 Sensors |

|

|

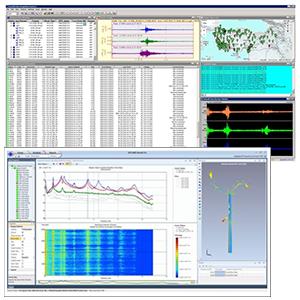

2 x Central Recorder |

|

|

Communication |

Integrated Into LAN |

|

Information |

data Center 1000SPS Permanent Data Recording |

|

Software |