NPP Beznau, Switzerland

The nuclear power industry is one where each country sets its own detailed quality and safety specifications within a framework that typically could include a high profile customer working in conjunction with consultants, safety bodies, main contractors and other interested parties as and when power generation requirements (either existing or new) reach a review stage. GeoSIG demonstrates the broad understanding of such complex business to business relationships by having completed nuclear power station projects for identified customers through having representatives in key areas around the world. GeoSIG collaborates with a number of affiliates within the nuclear industry field to ensure that their measuring instruments work within complete monitoring systems that meet output customer reporting requirements.

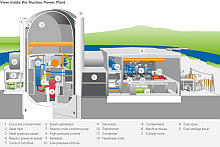

The scope of the Beznau Project was of a Seismic Monitoring System required to ensure that the Nuclear Power Station can receive sufficient warning to be safely shut down when seismic waves (motions) or other ambient dynamic earth activity has been detected by monitoring systems.

Evaluation and observation of nuclear power station structural safety and integrity is a mandatory requirement worldwide. Such comparisons are continually made of the structural movements measured against seismic design criteria reached for nuclear power generation buildings. The project scope included to develop and improve nuclear emergency and safety measures as well as awareness of the needs to contribute to regional seismic data management systems.

The scope of the Beznau Project was of a Seismic Monitoring System required to ensure that the Nuclear Power Station can receive sufficient warning to be safely shut down when seismic waves (motions) or other ambient dynamic earth activity has been detected by monitoring systems.

Evaluation and observation of nuclear power station structural safety and integrity is a mandatory requirement worldwide. Such comparisons are continually made of the structural movements measured against seismic design criteria reached for nuclear power generation buildings. The project scope included to develop and improve nuclear emergency and safety measures as well as awareness of the needs to contribute to regional seismic data management systems.

|

Solution |

Type |

Product |

|

6 x Sensors |

Triaxial Accelerometer |

|

|

6 x Strong Motion Recorders |

Strong Motion Recorder |

|

|

1 x Central Processing System |

Electronic Cabinet Computer Software |

|

|

Communication |

Fiberoptics |

Fiberoptic Interface |

The outputs are three nuclear power station system alarm levels are trigger, calculated, and system failure. Data is stored on an event basis, laser printed as three component time history.