Earthquake Early Warning

Introduction

- What is Earthquake Early Warning (EEW)?

- What is the goal of EEW?

- What is the difference between EEW and Rapid Response (RR)?

Methodology & Technology

- How do EEW solutions work?

- How do RR solutions aid emergency management and emergency response?

Our Solutions

- GMS Series Recorders for distributed and hybrid systems

- A wide variety of high quality sensors to measure acceleration and velocity

- Software solutions with highly customisable options

- Communication accessories for long distance installations

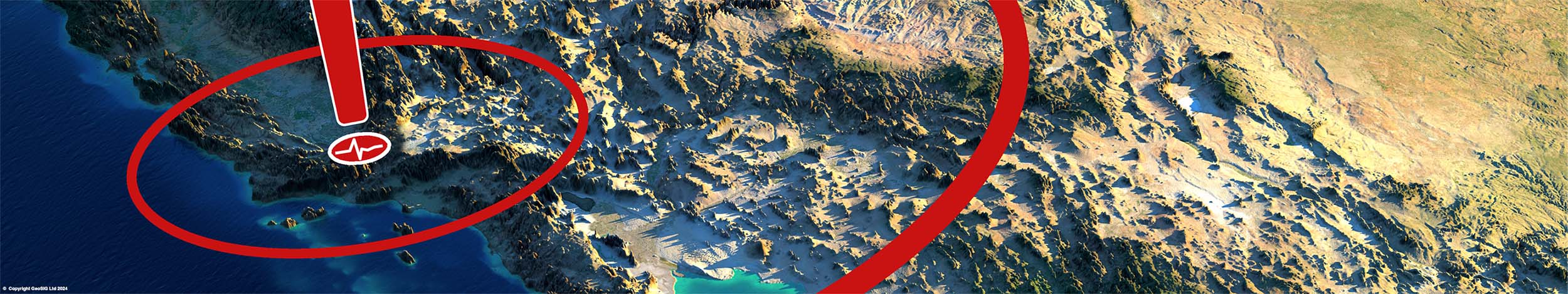

Earthquakes are a natural phenomenon caused most frequently by sudden movement along faults within the Earth. When this shaking causes severe damage or loss of life we label it as a disaster. Earthquakes can be dangerous, but at this time there is nothing we can do to prevent them nor to predict the precise time, location or size of an earthquake.

Methodology & Technology

- How do EEW solutions work?

The goal of Earthquake Early Warning is to provide warning ahead of an earthquake to enable people to take cover and take actions to prevent injury or damage. Depending on the warning system employed, alerts might come in the form of a public broadcast, public warning sirens, or even community-wide text alerts and messages on smart devices.

Based on fast and reliable communication channels, these warnings can provide the crucial seconds to take measures which may help reduce catastrophic impacts of seismic events.

- How do RR solutions aid emergency management and emergency response?

This short time lapse video demonstrates the concept and operation of Earthquake Early Warning systems available through GeoSIG.

This short time lapse video demonstrates the concept and operation of earthquake rapid response systems available through GeoSIG.

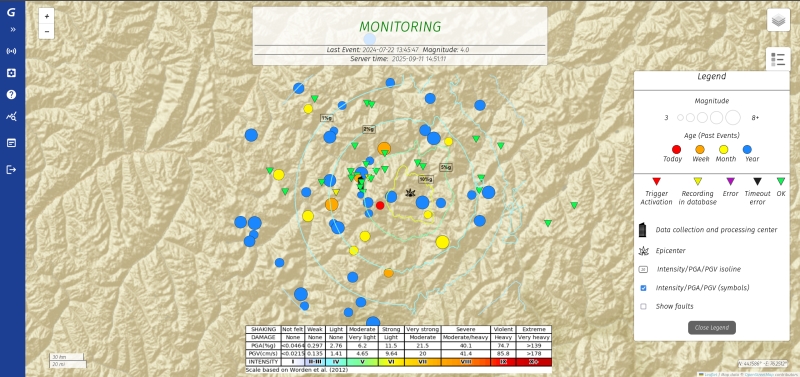

With technological and scientific advances, we are able to better prepare for pending disasters and mitigate their damage. GeoSIG is proud to instrument Earthquake Early Warning Networks and Rapid Response solutions around the world.