Download Case Study Honam High-Speed Railway

Background

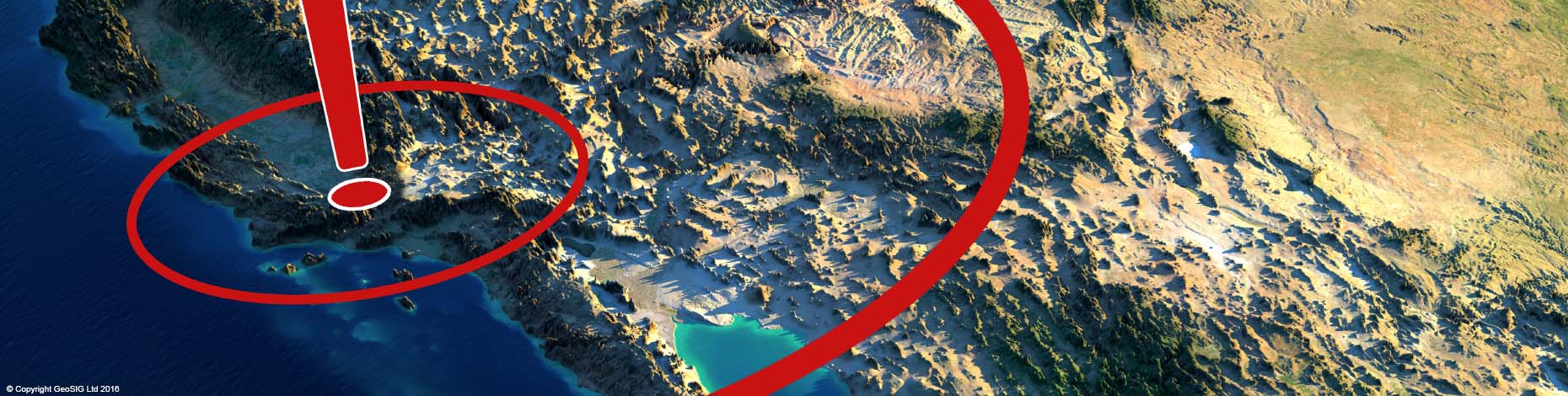

The Honam high-speed railway project was a large, national project budgeted at US $7 billion to build a new Korea Train Express KTX) to connect Osong station and Songjeong station in Gwangju, South Korea. The railway, which is 185 kilometers, began operation in April 2015. Thanks to this new high-speed train, travel time between Yongsan Station (Seoul) to Songjeong Station (Gwangju) was originally 2hr 39min, and is now reduced to 1hr 33min. The train’s maximum speed is 300km/h.

Challenge

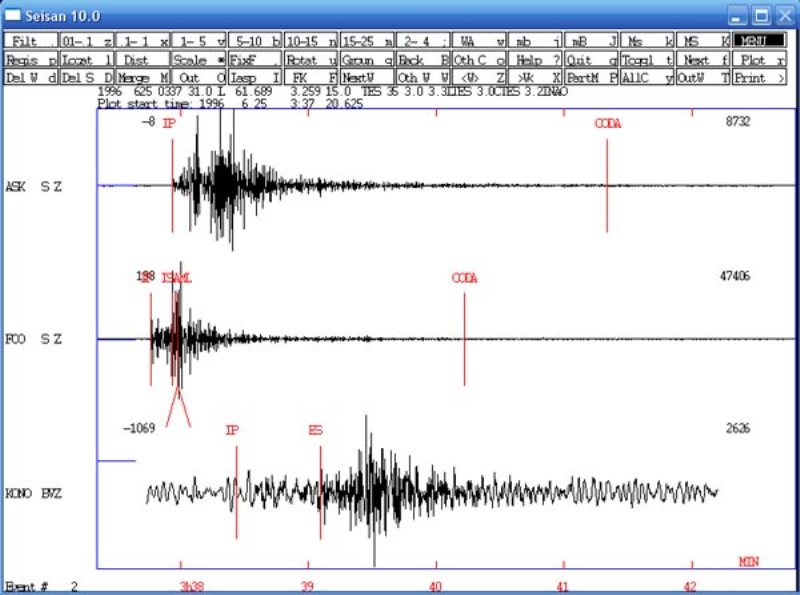

This is a high-speed rail service that traverses roadbed, bridges and tunnels, and stops at five stations. The train is equipped with 410 seats -- a significant number of passengers. In recent years, experts have warned that the Korean Peninsula is no longer safe from strong shock waves and called for disaster preventive measures. It was essential to have proper seismic and structural monitoring. Project leaders wanted to monitor the health and response of the infrastructure under operational- and earthquake-imposed loads as well as to improve safe operation of the trains. They wanted to have a system in place that would provide data they could use to establish a database at a national level for response to earthquake at facilities, and use this as reference/supporting data for the legislation or revision of earthquake- resistant design. They also wanted to support earthquake disaster reduction activity for prompt damage evaluation and response after an earthquake, and to help generate a seismic intensity distribution chart by measuring seismic acceleration.

Solution

Such an important project required a top-level engineering service with more than 20 years’ experience in seismic monitoring. Our partner, EJtech, was contracted to create the Honam high-speed railway Earthquake Monitoring System, which establishes a system to efficiently and safely control the high-speed train upon earthquake.

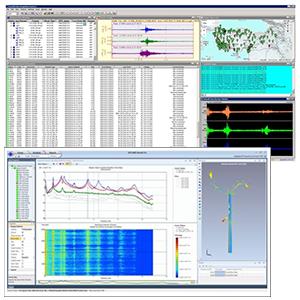

The CTC real-time high-speed railway seismic monitoring system encompasses 18 sites -- 13 bridges and five stations are monitored. For each bridge, four GeoSIG AC-71 sensors and three AC-73 sensors were installed, as well as a GMSplus recorder and two GMSplus6 recorders. The installations were located in the girder center, the pier top, the pier bottom and a free field location. For each station, three AC-71 sensors and two AC-73 sensors were installed, as well as a GMSplus and a GMSplus6. The installations were located in the top floor, the lowest floor and a free field location.

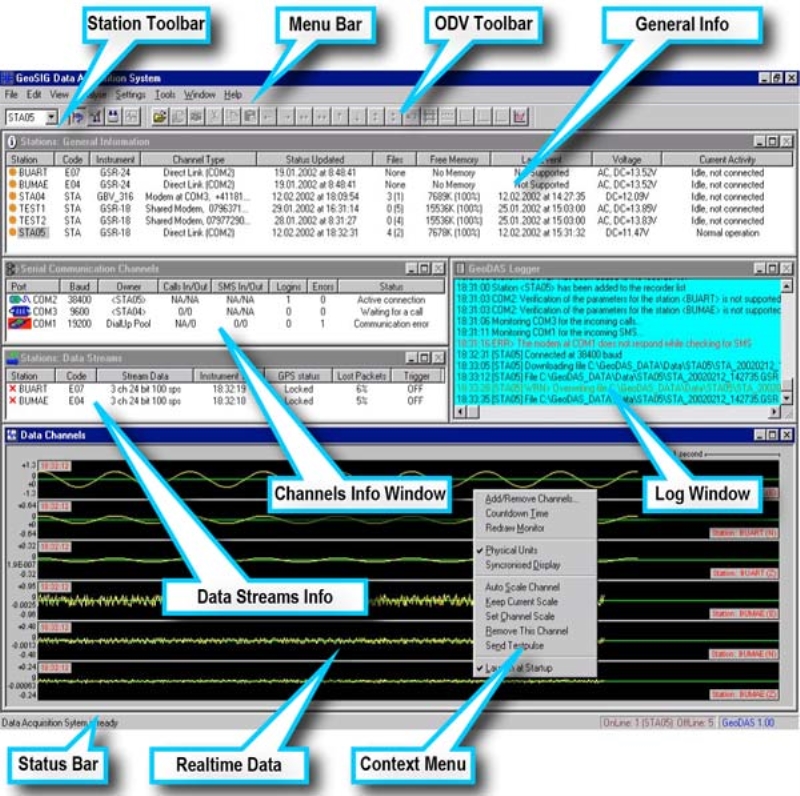

The system performs real-time earthquake and structural monitoring, issues warnings in case of exceedance of predefined thresholds, offers interactive surveillance, provides data for structural integrity evaluation and notifications for safe train operations. It also provides a connection between MPSS and other related organizations.

Another Solution using GeoSIG instruments and a capable Partner effectively showing that quality and reliability can also be cost-effective.

The CTC real-time high-speed railway seismic monitoring system encompasses 18 sites -- 13 bridges and five stations are monitored. For each bridge, four GeoSIG AC-71 sensors and three AC-73 sensors were installed, as well as a GMSplus recorder and two GMSplus6 recorders. The installations were located in the girder center, the pier top, the pier bottom and a free field location. For each station, three AC-71 sensors and two AC-73 sensors were installed, as well as a GMSplus and a GMSplus6. The installations were located in the top floor, the lowest floor and a free field location.

The system performs real-time earthquake and structural monitoring, issues warnings in case of exceedance of predefined thresholds, offers interactive surveillance, provides data for structural integrity evaluation and notifications for safe train operations. It also provides a connection between MPSS and other related organizations.

Another Solution using GeoSIG instruments and a capable Partner effectively showing that quality and reliability can also be cost-effective.