Download Sakhalin Oil and Gas, Russia Case Study

Background

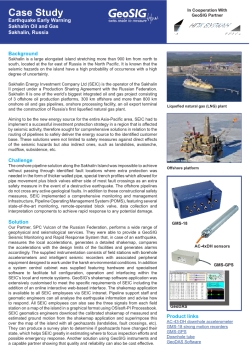

Sakhalin is a large elongated island stretching more than 900 km from north to south, located at the far east of Russia in the North Pacific. It is known that the seismic hazards on the island have a high probability of occurrence with a high degree of uncertainty. Sakhalin Energy Investment Company Ltd (SEIC) is the operator of the Sakhalin II project under a Production Sharing Agreement with the Russian Federation. Sakhalin II is one of the world’s biggest integrated oil and gas project consisting of 3 offshore oil production platforms, 300 km offshore and more than 800 km onshore oil and gas pipelines, onshore processing facility, an oil export terminal and the construction of Russia’s first liquefied natural gas plant.

Aiming to be the new energy source for the entire Asia-Pacific area, SEIC had to implement a successful investment protection strategy in a region that is affected by seismic activity, therefore sought for comprehensive solutions in relation to the routing of pipelines to safely deliver the energy source to the identified customer base. These solutions were not limited to safety measures against direct effects of the seismic hazards but also indirect ones, such as landslides, avalanche, mudflow, subsidence, etc.

Challenge

The onshore pipeline solution along the Sakhalin Island was impossible to achieve without passing through identified fault locations where extra protection was needed in the form of thicker walled pipe, special trench profiles which allowed for pipe movement plus block valves either side of most fault crossings as an extra safety measure in the event of a destructive earthquake. The offshore pipelines do not cross any active geological faults. In addition to these constructional safety measures, SEIC implemented a comprehensive monitoring and management infrastructure, Pipeline Operating Management System (POMS), featuring several state-of-the-art monitoring, remote-operated block valve, data collection and interpretation components to achieve rapid response to any potential damage.

Solution

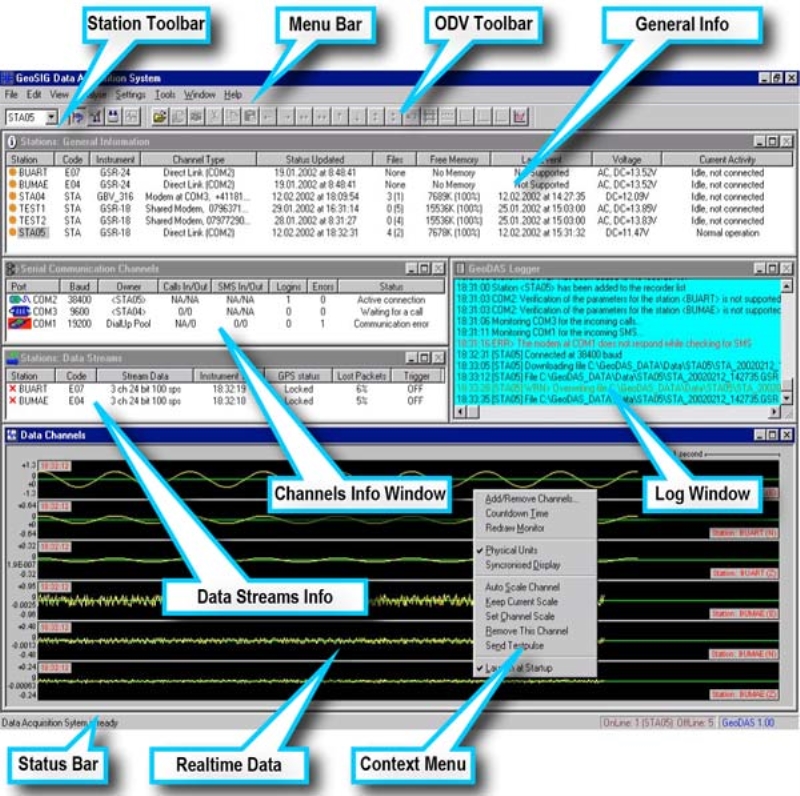

Our Partner, SPC Vulcan of the Russian Federation, performs a wide range of geophysical and seismological services. They were able to provide a GeoSIG Seismic Monitoring and Rapid Response System that, in case of an earthquake, measures the local accelerations, generates a detailed shakemap, compares the accelerations with the design limits of the facilities and generates alarms accordingly.

The supplied instrumentation consists of field stations with borehole accelerometers and intelligent seismic recorders with associated peripheral equipment designed to work under the harsh environmental conditions. In addition a system central cabinet was supplied featuring hardware and specialised software to facilitate full configuration, operation and interfacing within the SEIC’s local and remote systems.

GeoSIG’s shakemap software application was extensively customised to meet the specific requirements of SEIC including the addition of an online interactive web-based interface. The shakemap application is available to all SEIC employees via SEIC intranet. Pipeline support staff and geomatic engineers can all analyse the earthquake information and advise how to respond. All SEIC employees can also see the three signals from each field station on a map of the island in a graphical format using OSIsoft-PI Processbook. SEIC geomatics engineers download the calibrated shakemap of measured and estimated ground motion from the shakemap application and superimpose this over the map of the island with all geohazards (landslides, fault crossings, etc). They can produce a survey plan to determine if geohazards have changed their state, which helps SEIC greatly in estimating where to focus inspection efforts and possible emergency response.

Another solution using GeoSIG instruments and a capable partner showing that quality and reliability can also be cost effective.