Dams

Introduction

- What is seismic instrumentation and monitoring of dams?

- Why dams need seismic instrumentation and monitoring

- What are the advantages of seismic instrumentation and monitoring in dams?

Methodology & Technology

- How does seismic instrumentation and monitoring work?

Our Solutions

- GMS series recorders for distributed and hybrid system

- CR series modular multichannel recording systems for central and hybrid systems

- A wide variety of high quality sensors to measure acceleration, velocity, displacement, strain, tilt and environmental phenomena

- Software solutions with highly customisable options

Seismic Instrumentation and Monitoring of Dams is a particular branch in Structural Health and Response Monitoring, which is an innovative method of monitoring structural status and performance without otherwise affecting the structure itself and under earthquake excitations. It utilises also features from shutdown / notification systems. The basic concept is to deploy strong motion accelerometers and associated data acquisition / analysis systems in a dam to detect exceedance of allowed performance criteria as well as identify and verify structural behaviour.

• Why Dams need Seismic Instrumentation and Monitoring?

The strength and serviceability of a dam can be considerably—even terminally—reduced by natural or human-made events, earthquakes, extreme levels of operation, uncontrolled structural changes and various other influences.

Utilising seismic instrumentation and monitoring systems, timely notifications about any potential problems can be generated and behaviour of the dam can be monitored. The emerging use of seismic instrumentation and monitoring especially in the last decades, is a result of the increasing need for the monitoring of hazards and associated risks as well as a better management of the safety issues concerning the dams. This is further enhanced by the ongoing development and sophistication of sensors, data acquisition systems, communication technologies and other advances in technology.

In the past we have seen significant structural failures in dams due to earthquakes, such as Shih Kang Dam in Taiwan during the Chi-Chi earthquake in 1999. Events such as these drastically show how vulnerable dams can be if exposed to earthquake ground motions, ground deformation or overload.

Despite the progress in the dynamic analysis of dams, it is still not possible to reliably predict the behaviour of dams during very strong ground shaking due to the difficulty in modelling the inelastic behaviour of dams, the insufficient information on the spatial variation of ground motion and other factors. It is reported that the May 12, 2008 Wenchuan earthquake has damaged 1803 dams and reservoirs, and 403 hydropower plants with an installed capacity of 3.3GW (ref. Wieland, M., “Features of seismic hazard in large dam projects and strong motion monitoring of large dams”, 2009).

The factors that eventually lead to failure as well as their severity and effect on the structure can be measured and monitored with GeoSIG Seismic Instrumentation and Monitoring systems.

• What are the advantages of Seismic Instrumentation and Monitoring?

GeoSIG Seismic Instrumentation and Monitoring systems not only help reducing risks and costs, but also help avoiding disaster by its notifications which allows to initiate early damage detection and therefore helps saving lives as well as assets.

Utilising the acquired data by the system, fundamental features of a dam may be identified such as the damping within the large dam structure, amplification of the ground motion along the path from the foundation or abutments to the crest, wave propagation within the structure, differential motions between abutments, natural frequencies, mode shapes and so on.

In addition, the system allows to rapidly evaluate the structural response thus provides a highly useful measure for decision making whether to allow normal operation or to initiate a more comprehensive inspection before doing so.

The ideal Seismic Instrumentation and Monitoring system provides you with on-demand information about your structure's measured features, as well as warnings concerning any exceedance detected. Therefore also significantly reduces repair costs through early damage detection, making the monitored structure safer, increasing the cost efficiency of its maintenance.

Advantages of Seismic Instrumentation and Monitoring for Dams include:

• increased understanding of in-situ structural behaviour and characteristics

• assurance of structural resilience and serviceability

• reliable information based engagement of safety devices

• opportunity to facilitate the timely warning of the population living in the downstream valley

• factual data to check and to improve the seismic design criteria of the dam

• decreased down-time for inspection and repair

• development of rational maintenance/management strategies

• increased value of the assets when compared to non-monitored properties

and

• an increased effectiveness in allocation of scarce resources.

Additionally Seismic Instrumentation and Monitoring enables and encourages the reliable use of new and innovative materials and designs in engineering.

Methodology & Technology

• How does Seismic Instrumentation and Monitoring work?

Each dam is unique, therefore the monitoring system that must be applied is also singular. However there are typical system topologies which are recommended and have been in use since several years with success, which is fully covered by the long GeoSIG experience through more than 200 dam systems in place. In close cooperation with the owner/contractor, GeoSIG delivers tailor-made Seismic Instrumentation and Monitoring systems for each project.

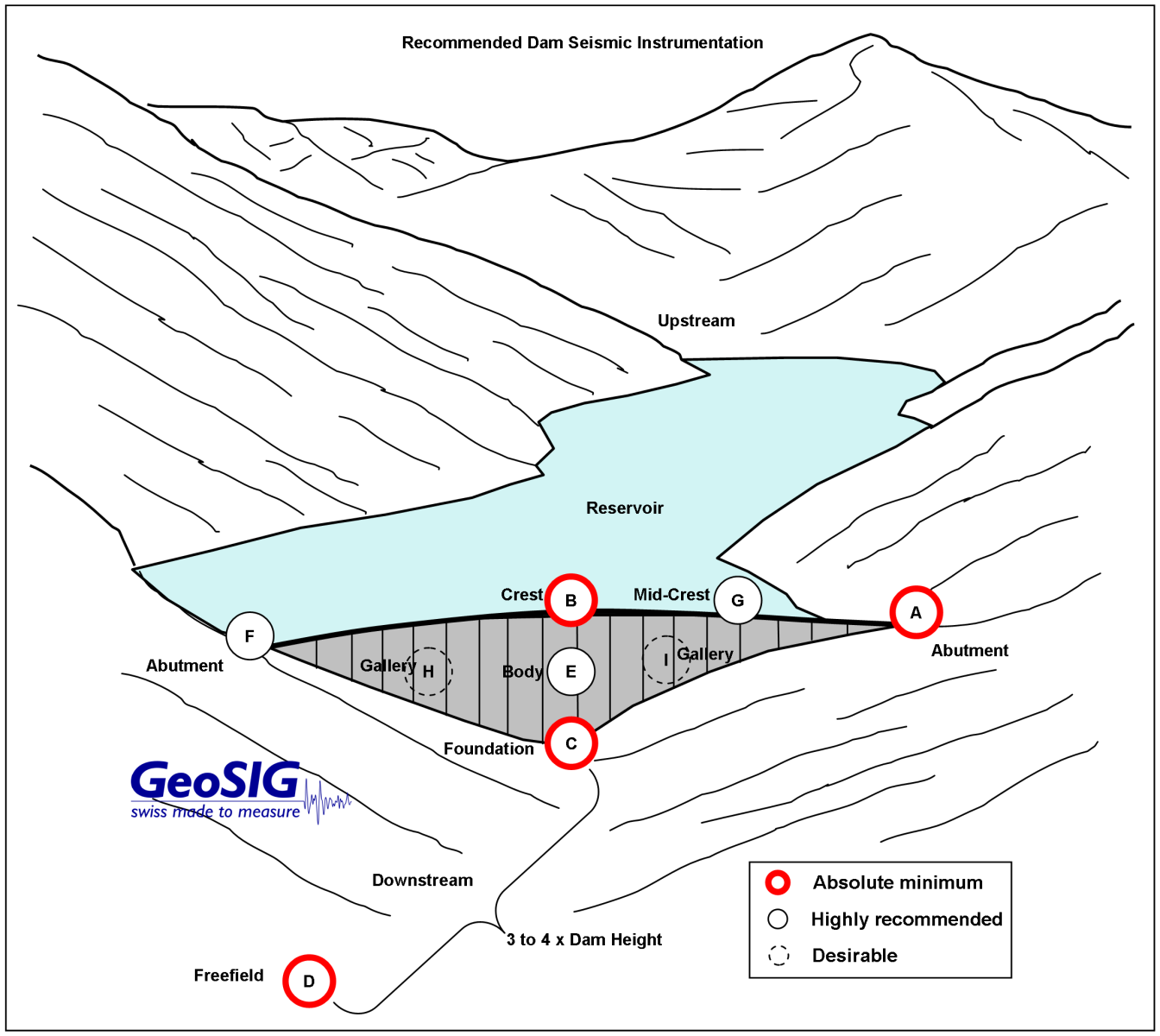

Typically an absolute minimum of 4 measuring points is foreseen, one in the base of the dam, one on the crest, one at an abutment and one at a freefield point at a distance that is approximately 3-4 times the height of the dam. Following image shows a recommended seismic instrumentation topology of a dam, please refer to the References section for further information.

At each measuring point a high dynamic mechanical force balance accelerometer is deployed. These devices collect raw acceleration data and transfer it to a Data Acquisition System (DAS). From the DAS, the data is collected and sampled. It can then be transmitted to an offsite location or stored locally for automatic, intelligent processing. The reliable level of remote monitoring eliminates the need for site visits. The system allows for tools to remove mundane data, noise, thermal, or other unwanted effects before storage, and to make data interpretation easier, faster and more accurate. Diagnostics convert abstract data signals into useful information about the structural response and condition.

Trigger levels for issuing warning signals or notifications (when previously defined values are exceeded) will be set according to its particular properties and capabilities, with reference to design, resistance, durability and stability.

GeoSIG Seismic Instrumentation and Monitoring solutions allow for the application of the Design versus Measurement methodology in terms of exceedance checks and notifications. Detailed state of the art and customisable data analyses are then used to enable reliable alerts and notifications in terms of email, SMS or visual and audible alarms. They even can be provided as automated relays to turn on or off desired machinery or operations. The results are automatically documented in customisable reports and can be automatically printed or transmitted to various recipients to enable rational, knowledge-based engineering decisions.

In essence, the variety of measurement, data acquisition and interpretation as well as notification and reporting techniques utilised by GeoSIG Seismic Instrumentation and Monitoring systems create “intelligent dams” that are safer, long-lasting, more secure, and cheaper to operate, maintain and insure.

References

COSMOS Instrumental Systems for Diagnostics of Seismic Response of Bridges and Dams 2001

Darbre G R Strong Motion Instrumentation of Dams 1995

Darbre G R Design Implementation of strong-motion Instrumentation Arrays in Dams 1992

Darbre G R State of practice in earthquake analysis of dams 2000

Darbre G R Dam Safety in Switzerland 2005

Fedock J USGS OFR 82-469 Strong Motion Instrumentation of Dams

FEMA-65 Federal Guidelines for Dam and Safety 2005

ICOLD B112 Neotectonic and dams Recommendations and case histories 1998

ICOLD B46 Seismicity and dam design 1983

ICOLD B52 Earthquake analysis for dams 1986

ICOLD B60 Dam monitoring General considerations 1988

ICOLD B62 Inspection of dams after earthquakes Guidelines 1988

ICOLD B68 Monitoring of dams and their foundations State of the art 1989

ICOLD B72 Selecting seismic parameters for large dams Guidelines 1989

ICOLD B74 Tailings Dam Safety 1989

ICOLD B87 Improvement of existing dam monitoring Recommendations and case histories 1992

ICOLD B98 Tailings Dams and Seismicity Review and Recommendations 1995

ICOLD B99 Dam Failures Statistical Analysis 1995

ICOLD Position paper Water Power dam safety and earthquakes Aug 2010

The National Academy of Sciences National Research Council Safety of Existing Dams 1983

Wieland M Earthquake safety of concrete dams 1994

Wieland M Earthquake Safety of Existing Dams 2006

Wieland M Earthquake Safety of Existing Dams 2006 Presentation

Wieland M Seismic Aspects of Dam Design 2002

Wieland M Strong Motion Instrumentation of Dams EN 2002

Wieland M Strong Motion Instrumentation of Dams Response 2002

Wieland M The many Features of the Seismic Hazard in Large Dam Projects 2009

Selected Dams Instrumented with GeoSIG Instruments

In the past decades, GeoSIG Instruments have been delivered to more than 300 dams in more than 40 countries, worldwide. Some of the dams around the world, which are instrumented with GeoSIG Instruments, are listed below.

|

|---|