Download Caren and Ovejeria Dams, Chile Case Study

Background

The great copper mines in Chile have experienced a continuous growth in mineral production rates in the last 30 years. This, coupled with low ore yield, has led to a significant increase in tailings production. In addition, the deposits of this mineral are of great dimensions, easily topping the thousand million tons of mineral. All of this indicates that the management and storage of the mine process waste has become significantly important in the design and operation of an existing or a new mine.

The Ovejeria Dam in Andina, Chile, took five years to build and has been fully operational since December 1999. Its estimated useful life is 50 years. It includes an 86 km concrete canal to transport tailings from an on-site concentrator plant to the dam, including 22 km of tunnels. Ovejeria receives more than 60’000 tpd of tailings material from Andina, (95% of everything extracted from the mine), which is scheduled to increase by almost to around 244’000 tpd after the mine’s next expansion stage.

Caren Reservoir, located 90 km SW of the city of Santiago, has served since 1986 for the disposal of tailings generated by El Teniente, the largest underground production copper mine in the world. The dam was designed in 12 stages with a final height of about 141 m, and it is estimated that by the end of its life the reservoir can store a total of 2,200 million m3 of tailings. As it stands today, the construction of stage 5 ends with a height of approximately 84 m. Approximately 600 million m3 of tailings are already stored in the dam. The lifetime of the Caren Dam is expected to be between 2054 and 2064, depending on the future rate of generation of tailings, currently at 130’000 tonnes per day.

Challenge

Chile is in the Ring of Fire. As a consequence of the March 1965 earthquake, the Chilean authorities issued in 1970 a norm to regulate the design, construction, and operation of sand tailings dams (Decree No. 86). This norm provided required deployment of strong motion instrumentation on tailing dams.

Solution

Our partner GeoMediciones / C. Fahrenkrog y Cia Ltda. has achieved a strong position in seismic monitoring systems and associated solutions in Chile and the surrounding region.

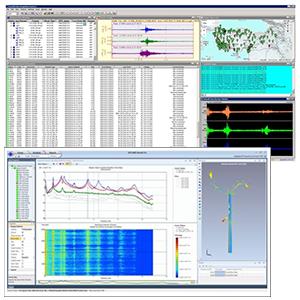

A configuration of 3 units of GSR-18 strong motion recorders with AC-63 triaxial accelerometers were deployed at Ovejeria, synchronized with GPS for timing, as well as solar panels, charge regulator and large capacity batteries were installed. The measurement locations were at free field, at dam foundation and at dam crest.

At Caren Tailing Dam, a configuration of 3 units of GSR-18 strong motion recorders with AC-63 triaxial accelerometers were deployed, synchronized with GPS for timing, as well as solar panels, charge regulator and large capacity batteries were installed. The measurement locations were at freefield, at dam foundation and at dam crest.

Once the data has been processed it is assessed and compared as dam behaviour against seismic design criteria applicable to dam operations. The project facilitated the development and improvement of dam emergency and safety measuring equipment within the context of increased awareness and contributed to the regional seismic data management systems.

Another Solution using GeoSIG instruments and a capable Partner effectively showing that quality and reliability can also be cost-effective.