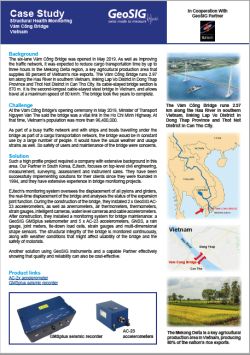

Download Vam Cong Bridge - Vietnam Case Study

Background

The six-lane Vàm Cong Bridge was opened in May 2019. As well as improving the traffic network, it was expected to reduce cargo transportation time by up to three hours in the Mekong Delta region, a key agricultural production area that supplies 80 percent of Vietnam’s rice exports. The Vàm Cong Bridge runs 2.97 km along the Hau River in southern Vietnam, linking Lap Vo District in Dong Thap Province and Thot Not District in Can Tho City. Its cable-stayed bridge section is 870 m. It is the second-longest cable-stayed steel bridge in Vietnam, and allows travel at a maximum speed of 80 km/h. The bridge took five years to complete.

Challenge

As part of a busy traffic network and with ships and boats travelling under the bridge as part of a cargo transportation network, the bridge would be in constant use by a large number of people. It would have the usual weather and usage strains as well. So safety of users and maintenance of the bridge were concerns.

Solution

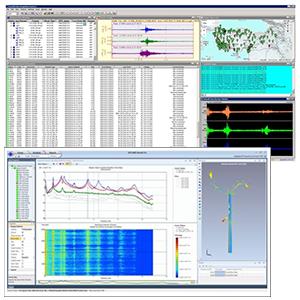

Such a high profile project required a company with extensive background in this area. Our Partner in South Korea, EJtech, focuses on top-level civil engineering, measurement, surveying, assessment and instrument sales. They have been successfully implementing solutions for their clients since they were founded in 1994, and they have extensive experience in bridge monitoring projects.

Another solution using GeoSIG instruments and a capable Partner effectively showing that quality and reliability can also be cost-effective.