Download NPP Krško, Slovenia Case Study

Background

Nuclear Power Plant Krško (NEK) has been providing stable production and reliable supply of electrical energy for its customers—no matter the weather—24 hours a day, every day since 1983. Located in Krško, Slovenia, NEK utilises a light pressurised water reactor. Up to 35 MW power is used for the plant’s own consumption, and the remaining 696 MW is transmitted through the 400-kV network to consumption centres in Slovenia and Croatia. Its annual generation of electrical energy covers approximately 20% of the electricity demand in Slovenia and 16% in Croatia. Customers have relied on NEK for decades.

Challenge

NEK’s seismic monitoring system was due for complete replacement due to obsolescence and operational and maintenance issues of the old system, as well as expansion of the system. Considerations for the new system included: the latest NPP regulatory guides, lightning strikes, electro-magnetic radiation, worst-case scenarios of radiation and high temperature affecting operability, and of course, safe shutdown in the event of an earthquake. The nuclear industry is the most highly regulated in the world when it comes to earthquakes, and whatever seismic monitoring system was installed would have to meet stringent nuclear industry mandates. This project would need to follow the latest guidance: US NRC Regulatory Guide 1.12; standard ANSI/ANS-2.2-2016 “Earthquake Instrumentation Criteria for Nuclear Power Plants”—particularly in regards to Design Basis Earthquake (DBE), Safe Shutdown Earthquake (SSE) and Operating Basis Earthquake (OBE).

Solution

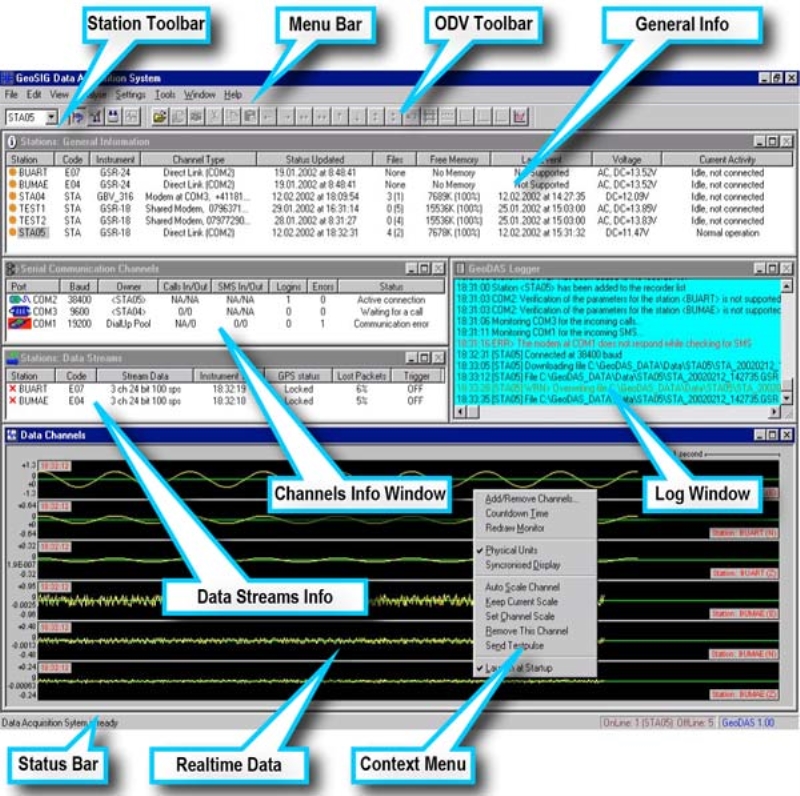

What was selected was a custom GeoSIG seismic monitoring system tailored to NEK’s needs. The old system was dismantled and the new system was extended in three stages. In the new system, (1) optical connections between the outdoor recorders in the main control cabinet in the Main Nuclear Island are used to avoid lightning impacts; (2) electrical lines between the accelerometers and recorders are designed and installed following up-to-date electro-magnetic compatibility qualification code requirements to avoid electro-magnetic interference; and (3) all in-housed recorders are relocated from the accelerometer locations into the main control cabinet in order to avoid negative radiation and environmental effects on the recorders. The entire system was seismically and EMC qualified.

The SMS system included a central SMS cabinet with GeoDAS software, eight AC-7x-NPP accelerometers in the nuclear island, 6 field stations with scai recorders and 8 more AC-7x-NPP accelerometers, a downhole AC-73-DH accelerometer, alarms to the main control room, and AC power supply source.

Another solution using GeoSIG instruments showing that quality and reliability can also be cost effective.